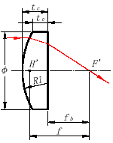

Plano-Convex Lenses is widely used in optical display systems, projection optics systems, imagining optical systems, and laser measurement systems.

Plano-Convex Lenses is widely used in optical display systems, projection optics systems, imagining optical systems, and laser measurement systems.

It is best to use where conjugate point– object distance, S or image distance S is more than five times of the other.

This lens is almost the most super form for both collimating a point source and focusing collimated light.

Applications:

●Optical Display Systems

●Projection Optics System

●Imaging Optics Systems

●Laser Measurements Systems

| BK7 Plano-Convex Lens | |

| Specifications: | |

| Material | BK7 grade A optical glass |

| Design Wavelength | 546.1nm |

| Design Index | 1.5183±0.0005 |

| Diameter Tolerance | +0.00/-0.15mm |

| Paraxial Focus Length | ±2% @546.1nm |

| Centration | see the table |

| Clear Aperture | >Central 85% of the diameter |

| Surface Figure | λ/4@632.8nm |

| Surface Quality | 60-40 S/D |

| Protective Bevel | <0.25mm x 45° |

| BK7 Plano-Convex Lens Standard Products: | |||||||

| Part No. | f (mm) | φ(mm) | R1(mm) | Centration | tc (mm) | te (mm) | fb (mm) |

| (arc minutes) | |||||||

| 4.0 | 2.0 | 2.073 | 15 | 1.26 | 1.0 | 3.2 | |

| 5.0 | 3.0 | 2.592 | 10 | 1.48 | 1.0 | 4.0 | |

| 6.0 | 4.0 | 3.101 | 3 | 1.5 | 0.77 | 5.0 | |

| 8.0 | 6.0 | 4.150 | 3 | 3.3 | 2.0 | 5.8 | |

| 10.0 | 6.0 | 5.180 | 3 | 3.0 | 2.0 | 8.0 | |

| 15.0 | 10.0 | 7.780 | 3 | 3.8 | 2.0 | 12.5 | |

| 22.0 | 10.0 | 11.400 | 3 | 3.1 | 1.9 | 20.0 | |

| 15.0 | 12.7 | 7.780 | 3 | 5.3 | 2.0 | 11.5 | |

| 20.0 | 12.7 | 10.370 | 3 | 4.2 | 2.0 | 17.2 | |

| 40.0 | 12.7 | 20.730 | 3 | 3.0 | 2.0 | 38.0 | |

| 50.0 | 12.7 | 25.920 | 3 | 2.8 | 2.0 | 48.2 | |

| 100.0 | 12.7 | 51.83 | 3 | 2.4 | 2.0 | 98.4 | |

| 40.0 | 20.0 | 20.730 | 3 | 4.5 | 1.9 | 37.0 | |

| 60.0 | 22.4 | 31.100 | 3 | 4.1 | 2.0 | 57.3 | |

| 25.4 | 25.4 | 13.170 | 3 | 11.7 | 2.0 | 17.7 | |

| 50.0 | 25.4 | 25.920 | 3 | 5.3 | 2.0 | 46.5 | |

| 50.8 | 25.4 | 26.351 | 3 | 5.2 | 1.9 | 47.4 | |

| 100.0 | 25.4 | 51.83 | 3 | 3.6 | 2.0 | 97.6 | |

| 200.0 | 25.4 | 103.66 | 3 | 2.8 | 2.0 | 198.2 | |

| 500.0 | 25.4 | 259.15 | 3 | 2.3 | 2.0 | 498.5 | |

| 1000.0 | 25.4 | 518.30 | 3 | 2.2 | 2.0 | 998.6 | |

| 35.0 | 30.0 | 18.155 | 3 | 9.9 | 2.0 | 28.5 | |

| 80.0 | 30.0 | 41.46 | 3 | 4.8 | 2.0 | 76.8 | |

| 100.0 | 30.0 | 51.83 | 3 | 4.2 | 2.0 | 97.2 | |

| 300.0 | 30.0 | 155.62 | 3 | 3.8 | 3.1 | 293.5 | |

| 50.0 | 38.0 | 25.920 | 3 | 11.3 | 3.0 | 42.6 | |

| 200.0 | 38.0 | 103.66 | 3 | 4.8 | 3.0 | 196.8 | |

| 700.0 | 38.0 | 362.81 | 3 | 3.5 | 3.0 | 697.7 | |

| 100.0 | 50.0 | 51.83 | 3 | 9.4 | 3.0 | 93.8 | |

| 200.0 | 50.0 | 206.28 | 3 | 6.0 | 3.0 | 198.0 | |

| 500.0 | 50.0 | 517.58 | 3 | 4.2 | 3.0 | 498.6 | |

| 800.0 | 50.0 | 828.64 | 3 | 3.8 | 3.0 | 798.7 | |

| 500.0 | 80.0 | 517.678 | 3 | 6.1 | 2.0 | 498.0 | |

| 250.0 | 100.0 | 257.0 | 3 | 13.7 | 3.9 | 245.4 | |

| Fused Silica Plano-Convex Lens | |

| Specifications: | |

| Material | UV grade fused silica |

| Design Wavelength | 546.1nm |

| Design Index | 1.46008±0.00005 |

| Diameter Tolerance | +0.00/-0.15mm |

| Paraxial Focus Length | ±2% @546.1nm |

| Centration | <3 arc minutes |

| Clear Aperture | >Central 85% of diameter |

| Surface Figure | λ/4@632.8nm |

| Surface Quality | 60-40 S/D |

| Protective Bevel | <0.25mm x 45° |

| Fused Silica Plano-Convex Lens Standard Products: | ||||||

| Part No. | f (mm) | φ(mm) | R1(mm) | tc (mm) | te (mm) | fb (mm) |

| 6.0 | 4.0 | 2.760 | 1.66 | 0.8 | 4.86 | |

| 10.0 | 5.0 | 4.600 | 1.74 | 1.0 | 8.81 | |

| 8.0 | 6.0 | 3.680 | 2.55 | 1.0 | 6.25 | |

| 10.0 | 6.0 | 4.600 | 2.12 | 1.0 | 8.55 | |

| 15.0 | 12.7 | 6.900 | 6.2 | 2.0 | 10.8 | |

| 20.0 | 12.7 | 9.200 | 4.5 | 2.0 | 16.9 | |

| 30.0 | 12.7 | 13.800 | 3.6 | 2.0 | 27.5 | |

| 40.0 | 12.7 | 18.400 | 3.1 | 2.0 | 37.9 | |

| 50.0 | 25.4 | 23.000 | 5.8 | 2.0 | 46.0 | |

| 75.0 | 25.4 | 34.510 | 4.4 | 2.0 | 72.0 | |

| 100.0 | 25.4 | 46.01 | 3.8 | 2.0 | 97.4 | |

| 200.0 | 25.4 | 92.02 | 2.9 | 2.0 | 198.0 | |

| 500.0 | 25.4 | 230.04 | 2.4 | 2.0 | 498.4 | |

| 1000.0 | 25.4 | 460.08 | 2.2 | 2.0 | 998.5 | |

| 50.0 | 38.0 | 23.000 | 13.0 | 3.0 | 41.1 | |

| 100.0 | 38.0 | 46.01 | 7.1 | 3.0 | 95.1 | |

| 200.0 | 38.0 | 92.02 | 5.0 | 3.0 | 196.6 | |

| 500.0 | 38.0 | 230.04 | 3.84 | 3.0 | 497.4 | |

Note:

Cutting Lens, Square Lens, Rectangle Lens and Coatings are available upon request.

Metal Mount is available upon request. Lenses with material B270, Pyrex, Sapphire, Silicon, Germanium, CaF2, ZnSe etc are also available upon request.

The general tolerance specifications above provide a guideline regarding manufacturing capabilities for optics ranging in size from diameter 0.6-350mm.

The manufacturing limits are not absolute; tighter tolerances may be possible.

Part specific tolerances may vary depending on component size, shape, and/or material.